With the rapid growth of global internet information, automation integration has become a mainstream trend. While the capabilities of smart networking and big data analytics have significantly improved, there are still some users who, without access to networked devices, often wish to record production recipe information after saving it and review it locally on their personal computers for analysis. Additionally, when an alarm occurs during machine operation, users want to understand the possible causes of the issue so that operators can perform basic troubleshooting themselves and reduce downtime-related losses.

Victor Taichung’s integration of Delta's AX8 controller makes it possible to operate effectively even in a non-networked environment. With built-in functions, users can download molding parameters via USB or perform basic troubleshooting based on fault prompts before FAE service personnel arrive. Two commonly used applications of these functions are introduced below:

1. Backup of Molding Parameters

The Delta AX8 controller provides a parameter storage function that allows users to save production settings (such as temperature, injection pressure, injection speed, etc.) as preset profiles. When producing the same product again, users can easily retrieve the saved parameter settings from a PDF file stored on a USB device, thus avoiding the hassle of reconfiguration and improving production efficiency. This feature not only enhances operational convenience but also ensures production consistency and reduces quality variations caused by incorrect or missing settings.

Usage Steps (as shown in Figure 1):

Navigate to the "Auxiliary Page" > "Auxiliary Functions" section.

Insert a USB drive (64GB or smaller) into the USB port located on the waterproof box on the right side of the front panel. Wait for the USB icon to appear.

Click on [Print Molding Parameters – PDF File], and after a few seconds, remove the USB to view the parameter report on a PC.

(Figure 1)

2. Alarm Log Analysis and Troubleshooting

The Delta AX8 controller includes a detailed alarm logging function. When an anomaly or fault occurs, the system automatically generates an alarm log and displays the cause of the issue. These logs help operators quickly understand the specific nature of the problem for accurate diagnosis. In addition to providing fault codes, the controller also displays possible causes and suggested troubleshooting steps to help users take prompt and appropriate actions. This reduces downtime and minimizes production losses.

Usage Steps (as shown in Figure 2):

Go to the "Auxiliary Settings" > "Alarm Messages" section.

Expand the list to view all alarm message records.

Select any alarm message you wish to review.

Then click on [Alarm Message Troubleshooting Guide] to view related explanations.

(Figure 2)

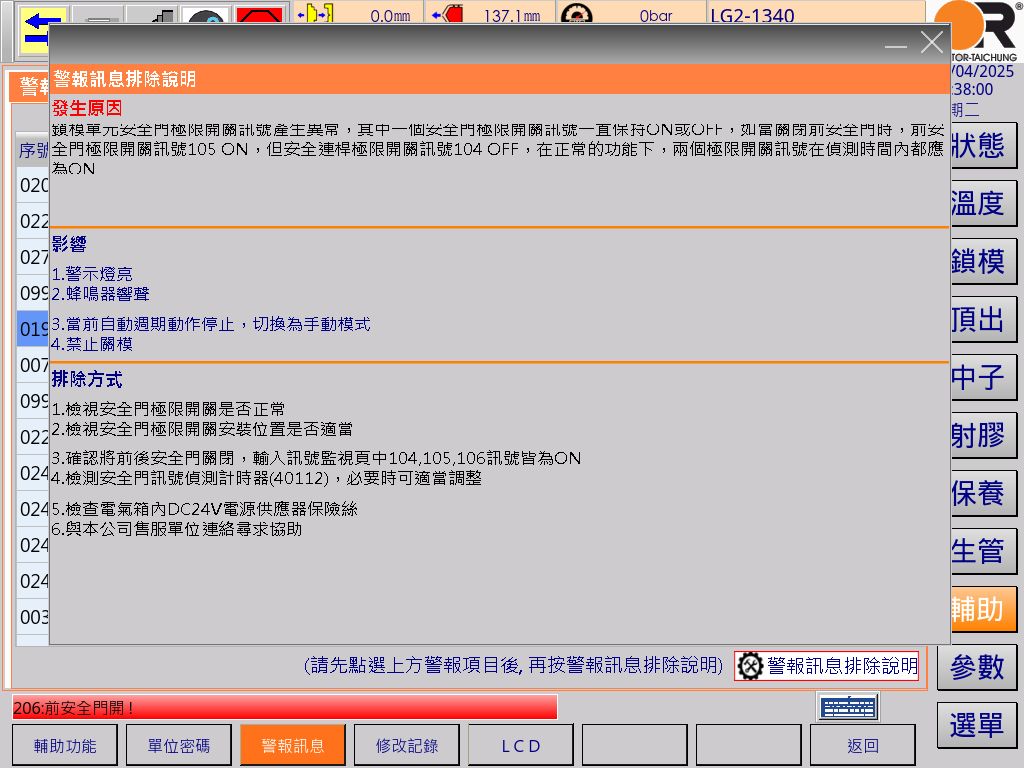

Troubleshooting Explanation and Method (as shown in Figure 3):

By utilizing these two functions, users can not only enhance the storage, comparison, and analysis of parameters but also achieve the practical benefits of unified and integrated management. Through precise parameter storage and alarm record analysis, users can quickly identify the root cause of a problem and take timely, accurate corrective actions. This approach significantly reduces downtime, prevents costs associated with equipment failure or setting errors, and improves overall production efficiency while ensuring product quality consistency.

When abnormalities occur on the production line, operators can immediately view or adjust the situation, avoiding errors and delays caused by traditional manual operations. Additionally, these smart functions enable enterprises to implement precise control, achieving efficiency and stability throughout the production process and boosting overall operational performance and competitiveness.

(Figure 3)

Applications of Delta AX8 Controller Functions for Plastic Machine

2025/05/06