All-electric Injection Molding Machine

Victor Taichung's new-generation all-electric injection molding machines are driven by servo motors, offering high precision, high efficiency, and low energy consumption. This new model equips with a second-generation electronic control system, the AX-8 pc-based motion controller, provides rapid response for pressure relief control to prevent overfilling or underfilling. The clamping mechanism features advanced acceleration and deceleration technology, it can reduce vibration during mold opening and closing for smooth operation and shorter molding cycles.

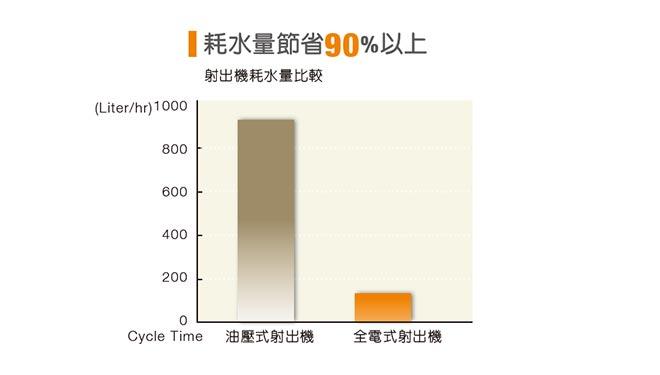

Compared to hydraulic machines, all-electric models save over 60% in energy and reduce cooling water requirements to 1/10. With energy-saving and eco-friendly advantages, all-electric models are especially applicable for medical, electronic, and precision parts manufacturing, making them an efficient solution for modern industries.

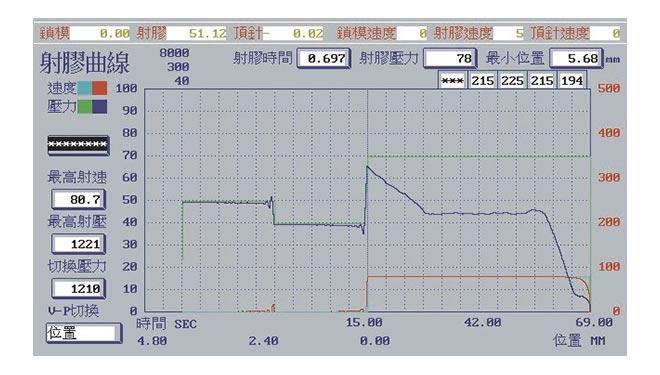

Peak

Pressure Suppression & Soft Pack Control

Injection speed decreases as filling progresses. Pressure maintained when

filling pressure reaches to the setting value.

No peak pressure,

residual stress reduced. Burr, gas burn, deformation improved. Lessening

variation in product weight. Elimination of flashes.

Lowering the

clamping force (low-pressure molding)

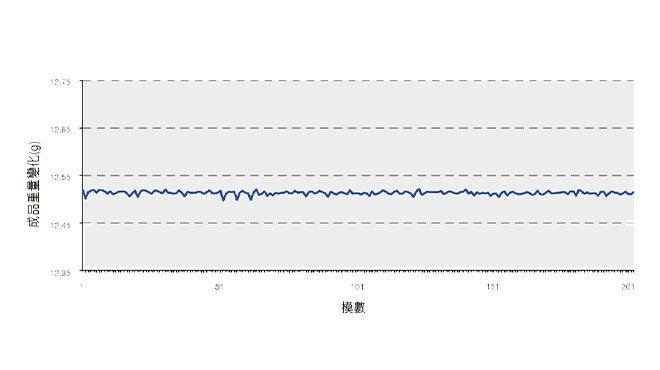

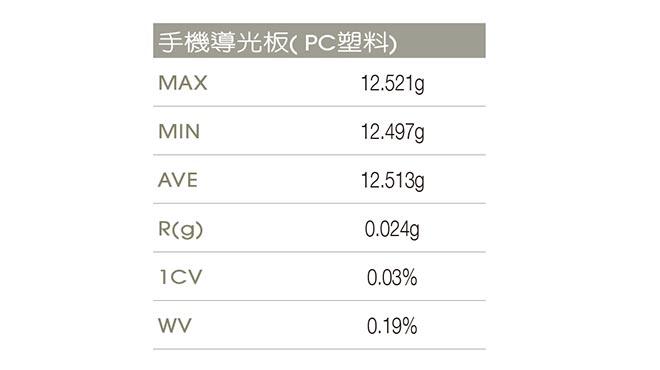

Stability of product weight

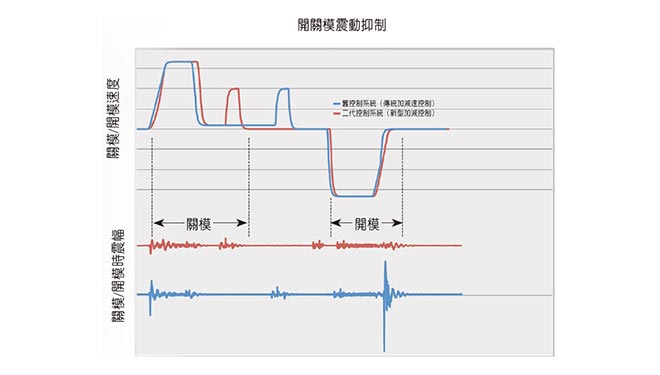

Optimized Mold open/close motion control

By optimizing ramp-up/down control and response times, the AX8 control system

delivers smoother mold operations. The S-curve acceleration/ deceleration

algorithm ensures a gradual transition between acceleration and

deceleration, minimizing wear and tear on mechanical components and

extending their operational lifespan.

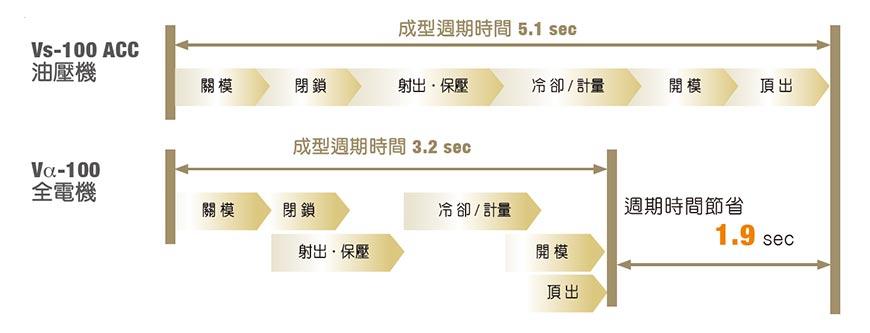

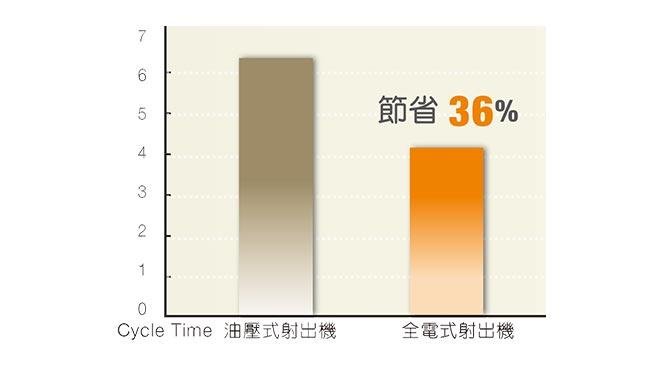

High Productivity

The electric servo-drive axes operate independently, providing high

precision, dynamic performance, and low noise emissions. Each axis has its

own dedicated drive, maximizing the benefits of this design

This

enables simultaneous operation of all machine functions and minimizes dwell

times.

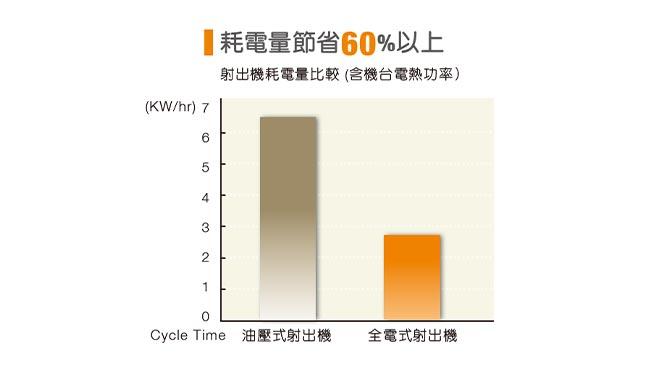

Test Data

- Product: Pudding Cup

- Cavities: Two Cavities

- Product Weight: 6.9 g/each

- Plastic: PP

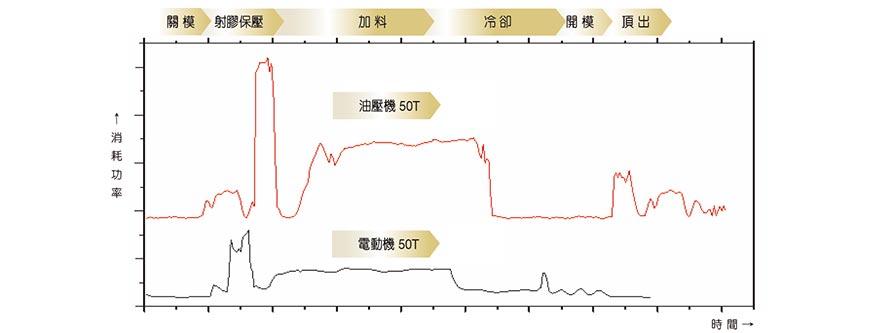

Reduce energy consumption by more than 60%

All-electric machines provide substantial

advantages over traditional hydraulic systems, particularly in terms of

energy efficiency and operating costs. By consuming 50-85% less power

compared to hydraulic machines, all-electric machines dramatically

reduce operating costs. Their power requirements are just 30% of those

for traditional hydraulics.

The servo-driven mechanisms in these

machines offer virtually lossless transmission output efficiency,

activating only when a command is issued. With precise digital controls

and mechanical drive systems, these machines deliver superior accuracy,

repeatability, and consistency, akin to precision machine tools and

robotics.

Lower energy usage also translates to reduced costs in

new plant construction, with benefits that include:

- Smaller electrical service connection hardware

- Less need for large busbars throughout the factory

- Smaller air conditioning compressors for temperature-controlled environments

- Cooling water needed only for the feed throat

- Electric machines contribute to fewer greenhouse gas emissions, offering you more environmentally and sustainable development option

Related

Links