Features

High-customization Development Rc-series

Insisting on "Technology innovation and quality superiority" Victor Taichung is continuously devoted to develop and produce new model of Rc double color (V-type and L-type) with servo-drive plastic injection molding machine to satisfy cus tomer's energy saving and repeatabilty requlrement.

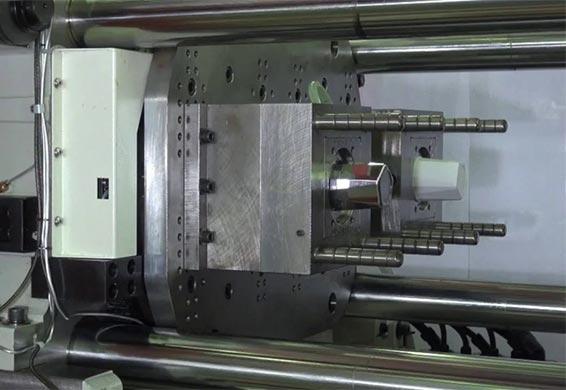

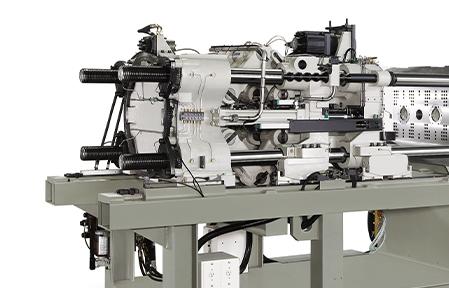

High Precision Injection Unit-Barbette Type Design

Two isolated injection cylinder and barrel sets inject at the same time with a powerful controller to satisfy your repeatability requirements! Designed for your universal processing applications.

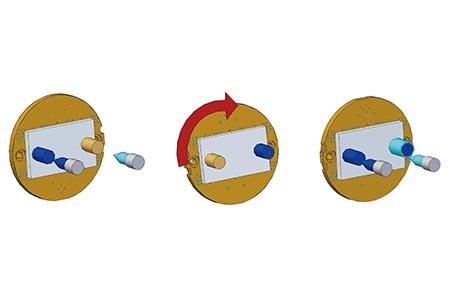

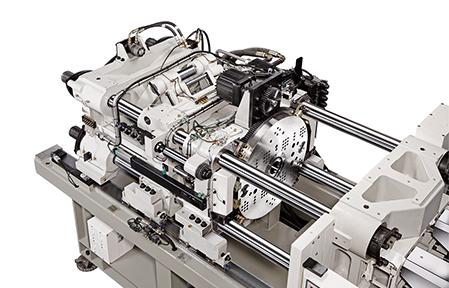

Rotary Table type of Injection Molding Machine

Using two injection units, users can mold products of two materials or colors in a single process. The double color injection molding machine is equipped with a 180° rotation plate with an accuracy reaching 0.01mm, which allows placement of two molds to produce double color products.

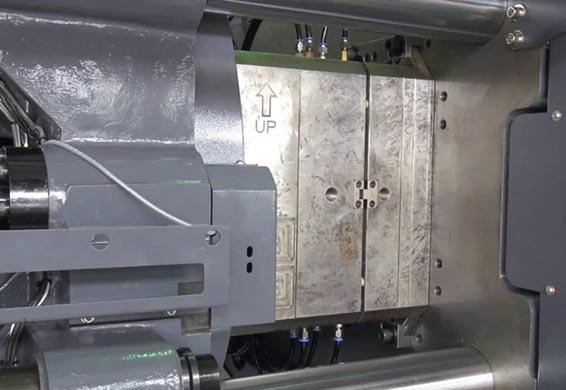

Special Clamping Unit Mechanism Design

Special mechanism design of the toggle has smooth and stable movement. Low-pressure protection device is utilized to prevent unintended damage of the mold. Toggle pins and bushings are manufactured from graphite impregnated phosphor bronze. Designed to run totally oil-free, there’s no chance of contaminating molds and maintenance is limited to long periodic greasing. And the auto lubrication system could extend the toggle life greatly. New generational toggle mechanism possess following characteristic as high strength, good flexibility, length of machine shorter than traditional toggle machines, and so on.

Mold Turning System Features

Rotary table rotating by servo-drive system during operation, the rotation plate does not come in contact with the platen, thus reducing the possibility of damage caused by friction. Besides, with accurate confirmation of the rotation position, it can protect the mold themselves. The positioner control use ENCODER and mechanical device double confirmed to advance precision of movement backward(s) and forward(s).

Mold Turning System Features

- The mechanism for rotating mold is possessed the function of rotation plate which could be suited with various dual color mold.

- Precise mechanism for fixed position is suited with high precision products.

- Rotation system is possessed high-speed, smooth and impact free movement.

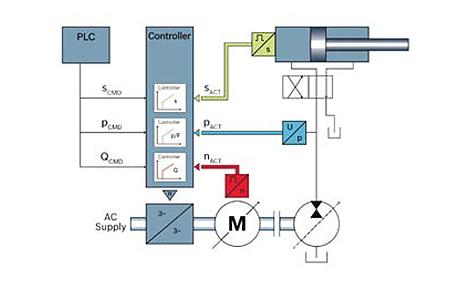

Energy Saving

Servo driven pump with variable speed drives for injection moulding machine.

Cost reduction by energy efficiency in Plastic Machinery.

Request on Drive System

- Reduced energy cost.

- Reduced installed power.

- Less secondar y measures for reduction of noise.

- Reduced cost for oil cooling.

Comparison with Traditional Fixed Pump with Constant Speed

Example: Load sensing

- 72.3% energy saving

- Model: VsES-50T

- 75s cycle times

- const. speed (15kW): 2.9 kW

- SVP: 0.8 kW

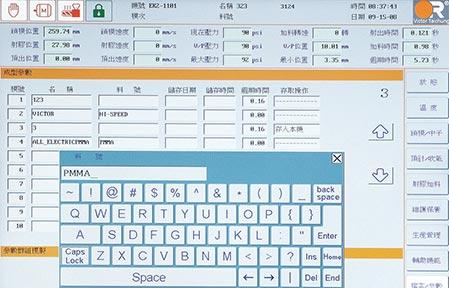

Intuitive 15 inch Touch Screen Framed with Keyboard

The swivel mounted 15" LCD high resolution touch screen, graphical user interface, can be optimally positioned for each operator, allowing an easy setting position and easy access to the mould area. Lighted on/off manual movement buttons for each axis.

Simple Friendly Operation Interface

Mold settings can be transferred using a USB drive The internal memory allows for up to 1000 set to be stored, the USB port enables molding condition files to be stored to an external USB memory stick.

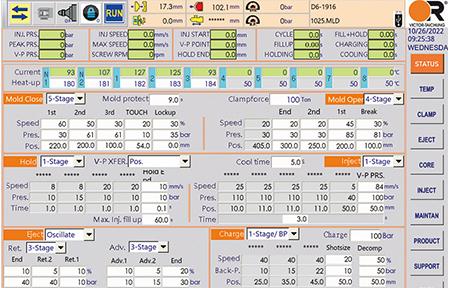

Overall Setting Screen

- Single screen for setting clamp, ejector, injection, temperature, air-blast and charging etc.

- Great for quick setups and adjustments.

- Improves operator setup efficiency.

Pop-up Keyboards for Data and Text Entry

Touch screen panel/Pop-up keyboard for data and text entry. Drop down selection boxes for choosing items from a list.

SPC/SQC Production Management - Quality Control

Process cycle data maintains information over the last 500 cycles allowing for quick analysis of process history. This data can be printed, and save to USB sticker, for off line analysis.

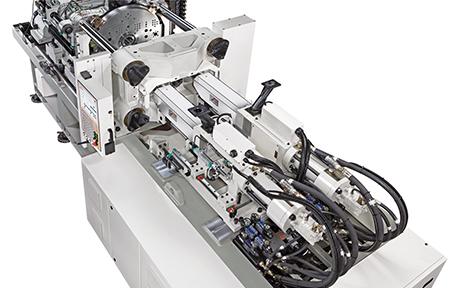

Customization Injection System Module (V-type & L-type)

With different mold design, use mold rotating and platen rotary device by one or moreslide of the core pulling system control, the second material injected into the mold cavity preparation. With customized specifications of the vertical or horizontal control secondary injection, to achieve a variety of colors and multi-level special effects.

* Horizontal Injection system module specification of L-type (Suitable for VE/VsP/VR series)