Features

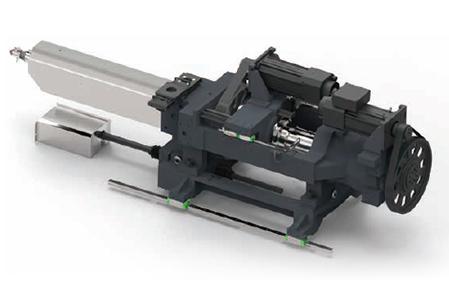

Clamping Unit

- The robust clamping unit ensure fast-cycle molding.

The high-rigidity clamping unit with linear pressure toggle mechanism enables the use of wider platens and achieves high-precision stabilized molding. - Platen support and bushless tie bars

The movable platen is supported with linear guides to maintain a high degree of parallelism accuracy even when heavy molds are mounted.

Less grease is needed around the movable platen since it has no tie bar guide bushes. -

Platen structure optimization

Square structure with concentrated crank force design, reduce platen distortion.

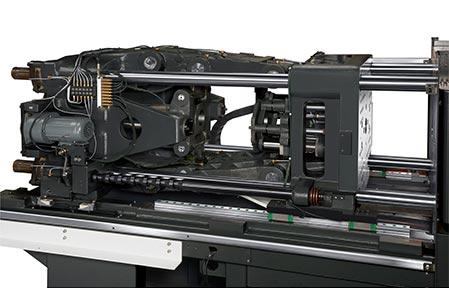

Injection Unit

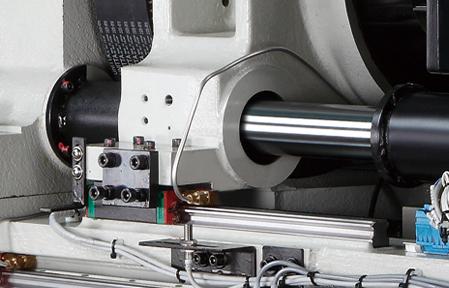

- Pivoting injection unit

130-250 Tons provide manual rotation of the injection unit. Easier for repair or replacement without remove the mold. - High rigidity injection structure

Injection casting Integrated design and all processed synchronized, high strength and precision.

The Robust Clamping Unit

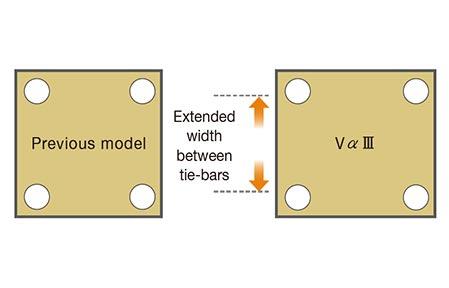

- The horizontal tie bar distances are extended further than conventional machines to allow for wider molds.

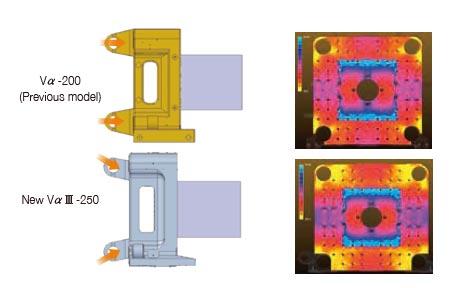

. The center-pressed structure movable platen it offers uniform contact pressure and twist-resistant structure. It hardly causes flash, making reduction and

optimization of clamping force easy. Contact pressure around the locating ring has been improved significantly.

. Victor's 5-joint Internally Folding Toggle System Enables a Faster Clamp Action

. The latest 3D simulation software has been utilized to analyze the design and structure of the new toggle system. This has enabled the use of a shorter ballscrew and reduced the mold open / close time.

Centrally Pressed Platen Structure, Improved Force Distribution

The moving platen incorporates a rigid box design cast platen- which is FEM optimized to ensure minimum deflection, maximum control and toggle linkage durability.

The centrally pressed platen design reduces platen deflection, this together with increased platen rigidity improves the force distribution and eliminates short shot and flash problems.

Victor's 5-joint Internally Folding Toggle System Enables a Faster Clamp Action

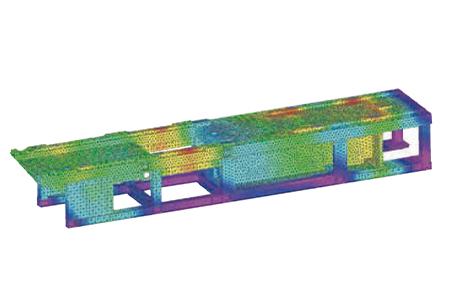

The latest 3D simulation software has been utilized to analyze the design and structure of the new toggle system. This has enabled the use of a shorter ballscrew and reduced the mold open / close time.

Hard to Deflect / Hard to Twist

Hard to deflect, hard to twist- Tubular steel frame i s featured on Vα machines for maximum rigidity with multi-directional parts removal.

Powerful, High-speed Quick Response Injection Unit

- Precision linear guide bearings are used on the injection unit carriage for smooth and reliable sled movement.

- Japanese manufactured load cell produces high resolution results, fast injection response and the precise pressure control required for precision molding.

- The new designed linear guides are optimized for quicker acceleration loads and faster cycles required for thin-wall molding.

A New Low-friction Linear Guide

A new low-friction linear guide is adopted for supporting and driving the movable platen,

enabling friction free movement from extreme low to high velocity.

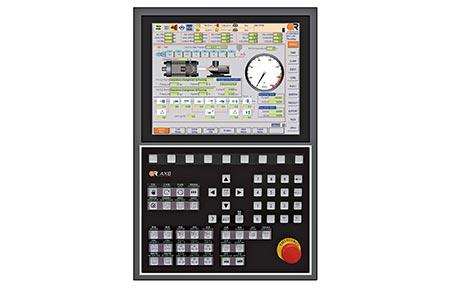

Intuitive 15 inch Touch Screen Framed by a Keyboard

The swivel mounted 15" LCD high resolution touch screen, graphical user interface.

- Can be optimally positioned for each operator, allowing an easy setting position and easy access to the mould area.

- Individual forward and retract manual movement buttons for each axis.

- The advanced 4KHZ high speed servo control scanning time achieves high precision injection control for high precision molding.

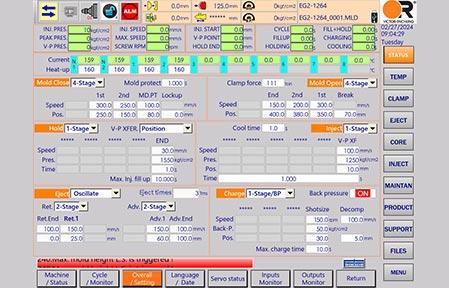

Simple Friendly Operation Interface

Mold settings can be transferred using a USB drive

The internal memory allows for up to 1000 molds to be stored, the USB port enables molds to be stored to an external USB memory stick.

Set Point Overview Screen

- Single screen for setting clamp, ejector, injection, temperature, air-blast and charging etc.

- Great for quick setups and adjustments.

- Improves operator setup efficiency.

Pop-up Keyboards for Data and Text Entry

Touch screen panel/Pop-up keyboard for user friendly setting and operation.

Production Management - Quality Control

Records various quality control and production metrics and has the facility to set machine stop conditions.

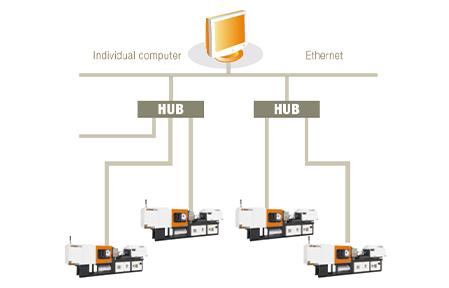

Remote monitoring system PIS (Option)

Quiet, Clean Operation Environment

An independent 3-path centralized greasing system manages the proper lubrication amounts and intervals to the ballscrew and toggle-pin sections.

Accessories

Standard :

- Tool/ fuse kit

- Part drop chute

- Standard 5-in's/ 5-out's water regulator without flow indicator

- Anti-vibration leveling pads

- 220V/ 380VAC outlet x 1 for auto loader

- Transformer for local power source

Optional :

- Conveyor belt

- 4 or extra zones water regulator with the flow indicator

- 110VAC outlet receptacle (power sourced by customer)

- 110VAC outlet receptacle (power sourced via machine)

- AC 220V/ 380VAC outlet receptacle (power sourced by customer)

- AC 220V/ 380VAC outlet receptacle (power sourced via machine)