Features

60-260 Tons VsP Series Simple, Productive, Economical

- Energy saving-almost equivalent to all- electric model machine.

Quick response-Injection response time (Standard mode). - Stability in low-velocity/low-pressure & wide range-Injection velocity: From ultra-low to high velocity range.

- Linearity-Excellent linearity in both injection velocity and injection pressure.

60-260 Tons VsP Series Simple, Productive, Economical

- Excellent injection holding pressure performance-Capability in sustaining high injection holding pressure longer (as compared with full-electric machine).

- Reduction in the amount of hydraulic oil and cooling water volume.

- Silent! (Low noise gear pump operation) Almost equivalent to all electric injection molding machine.

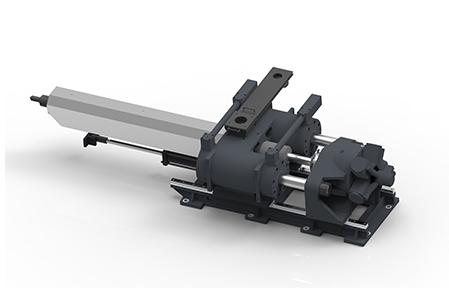

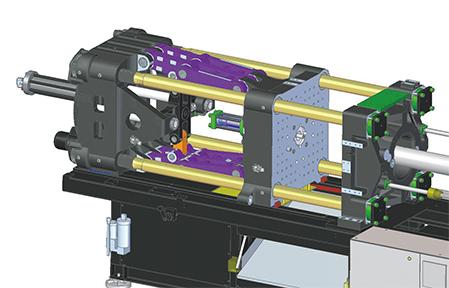

High Precision Injection Unit

The VsP Series optimum screw geometry plus the perfected drive and injection concepts provides excellent plasticising and injection capacity. Newly developed high wear and corrosion resistance ion-nitrided screw and barrel gives the customer a wide choice of materials for numerous applications.

The gently prepared and properly homogenised melt is metered accurately, shot after shot, and is injected into the mould with high power and high speed.

The Screw and Barrel Used on the Victor Machines has the Following Properties.

- Injection screw ACM2 German material

- Surface hardness: 900~1100 HV

- Processed by Nitride (500~520℃ for 72hrs)

- Nitrided thickness: 0.4~0.5 mm

Bi-metallic Material (Optional)

SKD 61 base material. Excellent wear-resistant, corrosion resistant screw & barrel for the processing of materials with fiber additives and also fire retardant materials.

Victor general purpose screw and barrels can process any kind of material like PE, PP, PA, ABS, AS. We also supply an optional screw & barrel for engineering materials like PC, PBT, PET, with an L/D ratio from 18, 20, 22.

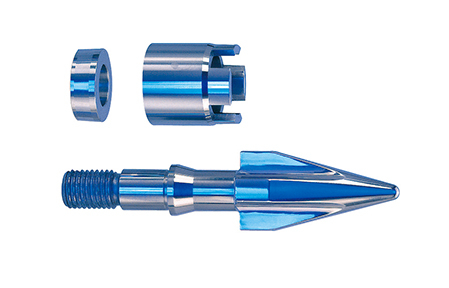

The Multi-notch Locking Style Screw Tip.

The locking style tip is useful for stabilizing part weight and increasing product precision comparing the convectional screw tip. the gap between the screw and check ring is reduced to the least, thereby the back flow resin can be reduced to minimum.

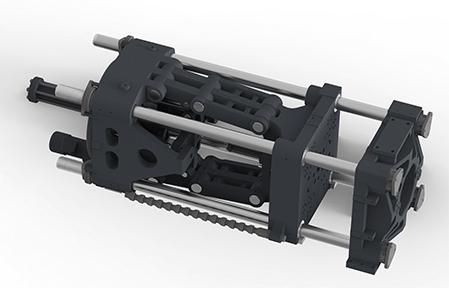

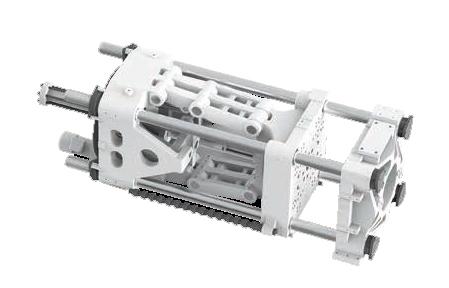

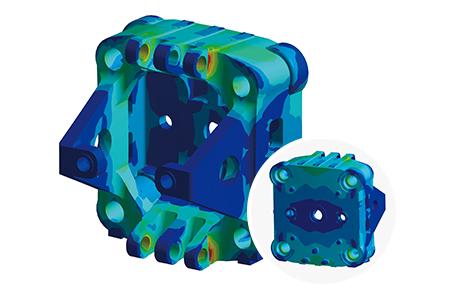

Heavy Duty, Rigid, Clamping Unit

Every component in the clamping unit that is subjected to a mechanical stress was designed and checked using the F.E.M (Finite element method) method of structure analysis. All VsP Series machines feature a unique, ultrareliable, five-point toggle clamping mechanism, which is characterised, by an almost ideal kinematic velocity feature. This system has fast speed, high force ratio, sensitive mould protection and good energy saving capabilities. The large square cast iron platens are extremely robust and the widely spaced tie bars allow for even the most complex of moulds.

Eliminate Deflection and Oil-free

The large, square cast iron platens virtually eliminate deflection. The bushings a re manufactured from graphite impregnated phosphor bronze. Designed to run totally oil-free, there's no chance of contaminating molds, and maintenance is limited to long periodic greasing.

Material

- Platen: Meehanite casting FCD 55

- Tie bar: NH48MV (from Japan)

- Toggle pin: SCM440 (hard chrome plating)

Advantage

- Machine life = 15 years more

- Eliminates the oil pollution

- Saves maintenance time

Prevent of Overloading by Force

Mould height adjustment, which is the bull gear system, is operated by an electrical brake motor and when co-ordinated with a precision circuit breaker proceeds to prevent the possibility of overloading by force and cause machine damage.

Energy Saving System (Option)

The VsP Series (150T~260T models) adopts logic valves in its hydraulic system circuits. The logic valves give high response performance in injection and mould travelling stages and offers 5% energy reduction due to low-pressure loss, and can guarantee a long service life. Less energy loss means lower heat build-up in addition to a substantial reduction in the requirement of cooling water. This is further help automatic regulation of the hydraulic oil temperature.

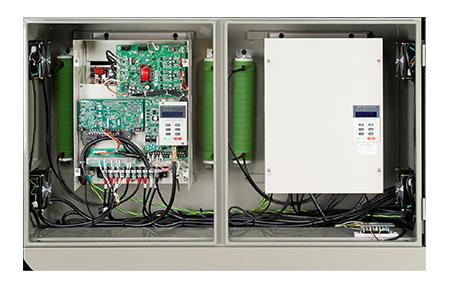

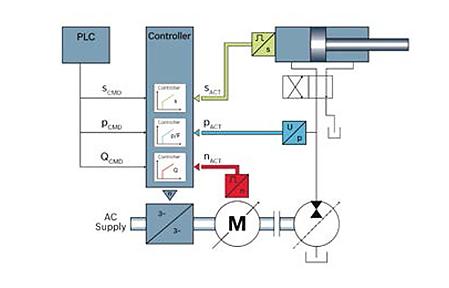

VsP Energy Saving SVP System (Injection Close-loop Feedback Control)

The pressure transducer measures the real injection cylinder and feedback to P/Q control module for the close-loop pressure compensation. The servo motor rpm encoder measures and feedback the pump flow to P/Q control module for the speed compensation to get precision relativity control.

Comparison with Traditional Fixed Pump with Constant Speed

Example: Load sensing

72.3% energy saving

Model: VsP-60T

75s cycle times

const. speed (15kW): 2.9 kW

SVP: 0.8 kW

Hybrid Hydraulic Control (Option - Servomotor Pump)

VsP Series injection molding machine every moving steps require pressure and flow control by high-efficacy gearpump collocating with powerful permanentmagnet synchronous servo motor. This series machine is availability of energy saving up to 60~75% as compared with the traditional hydraulic machine.

Servo Driven Pump with Variable Speed Drives for Injection Moulding Machine

Cost reduction by energy efficiency in Plastic Machinery.

Request on drive system

- Reduced energy cost.

- Reduced installed power.

- Less secondary measures for reduction of noise.

- Reduced cost for oil cooling.

Piston Seal Uses UK Made Hallite to Reduce the Leakage and Extend Piston Life

- Piston seal: Hallite(UK)

- Cylinder seal: NOK (Japan)

- O-Ring: NOK (Japan)

- Back-up Ring: NOK (Japan)

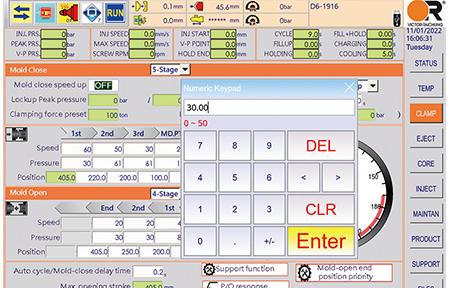

New Generation V8800 Control

Intuitive 15 inch touch screen framed with keyboard

The swivel mounted 15" LCD high resolution touch screen, graphical user interface, can be optimally positioned for each operator, allowing an easy setting position and easy access to the mould area. Lighted on/off manual movement buttons for each axis.

Simple Friendly Operation Interface

Mold settings can be transferred using a USB drive

The internal memory allows for up to 1000 set to be stored, the USB port enables molding condition files to be stored to an external USB memory stick.

Overall Setting Screen

- Single screen for setting clamp, ejector, injection, temperature, air-blast and charging etc.

- Great for quick setups and adjustments.

- Improves operator setup efficiency.

Pop-up Keyboards for Data and Text Entry

Touch screen panel/Pop-up keyboard for data and text entry. Drop down selection boxes forchoosing items from a list.

SPC/SQC Production Management - Quality Control

Process cycle data maintains information over the last 10,000 cycles allowing for quick analysis of process history. This data can be printed, and save to USB sticker, for off line Excel analying.