Features

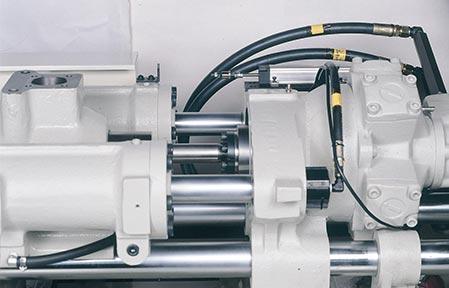

High Precison Injection Unit

Nitrided screw & barrel, wear-resistant screw tip, high injection volumes and plasticizing capacities at high injection speed.

Capable of profile injection with up to five pressure speeds and distance settings, variable back pressure control and shot repeatability is extremely accurate. It all adds up to a unit that will stay the course, giving

consistently high quality and output with a wide range of material s and with the most complex of moulds.

The Screw and Barrel Used on the Victor Machines has the Following Properties.

- ACM2 German material

- Surface hardness: 900~1100 HV

- Processed by Nitride (500 ~ 520˚C for 72hrs)

- Nitrided thickness: 0.4 ~ 0.5 mm

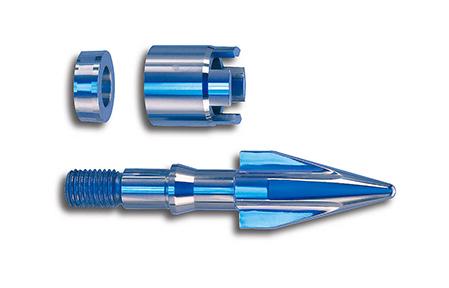

Multi-notch Non-return Valve (Optional)

This multi-notch non-return valve offers improved reaction times and high flow rates. Also improves cycle times and increases product precision.

- Pos i t ion rod uses S45C steel, which has excellent strength.

- Position seal uses German make Merkel to reduce the leakage and extend piston life.

Bi-metallic Material (Optional)

Bi-metallic material (optional) - SKD 61 base material.

Excellent wear-resistant, corrosion resistant screws & barrels for the processing of materials with fiber additives and also fire retardant materials. Victor general purpose screw and barrels can process any kind of material like PE, PP, PA, ABS, AS. We also supply an optional screw & barrel for engineering materials like PC, PBT, PET, with an L/D ratio from 18, 20,22,24

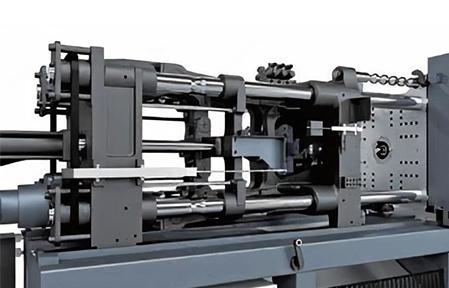

Heavy Duty, Rigid, Clamping Unit

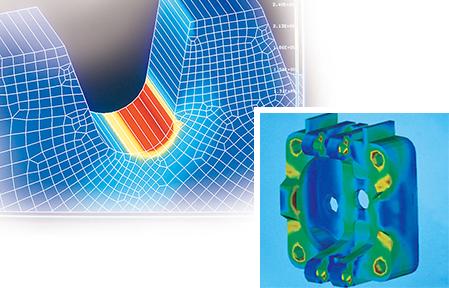

A unique, ultra-reliable, five-point toggle clamping mechanism offering distinct advantages over conventional systems with its strong casted platens stressed analyzed tie-bars and a consistency not to be match.

The large, square cast iron platens are extremely robust, virtually eliminating deflection and with widely spaced tie bars.

The bushings are manufactured from graphite impregnated phosphor bronze. Designed to run totally oil-free, there's no chance of contaminating molds, and maintenance is limited to long periodic greasing.

Material

- Platen: Meehanite casting FCD 55

- Tie bar: NH48MV (from Japan)

- Toggle pin: SCM21 (hard chrome plating)

Advantage

- Machine life = 15 years more

- Eliminates the oil pollution

- Saves maintenance time

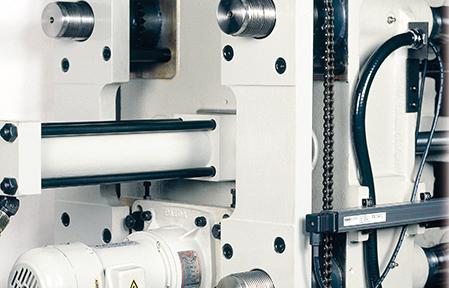

Mould Height Adjustment

Mould height adjustment, which is the chain mechanism system, is operated by an electrical brake motor and when co-ordinated with a precision circuit breaker proceeds to prevent the possibility of overloading by force and cause machine and mould damage.

Precision Hydraulic System

The moving force behind every Ve-series is a carefully designed, ultra-quiet, leak- free hydraulic system, quick responsive hydraulic circuit. Featuring high quality components, including the latest proportional valve technology, the system combines excellent repeatability and rapid response times (40 milliseconds) with very low energy consumption, and maintenance could be easier with clear access to all major components.

VE Energy Saving SVP system - Optional

injection close-loop feedback control

The pressure transducer measures the real injection cylinder and feedback to P/Q control module for the close-loop pressure compensation. The servo motor rpm encoder measures and feedback the pump flow to P/Q control module for the speed compensation to get precision relativity control.

High Quality Directional Valves

High quality directional valves from Yuken and Tokimec for high-speed response, reliable operation and optimum energy savings. The latest proportional control valves, from Yuken, gives the optimum performance for the pressure and volume settings.

Piston Seal Uses UK Made Hallite to Reduce the Leakage and Extend Piston Life.

- Piston: Piston seal: Hallite (UK)

- Cylinder seal: NOK (Japan)

- O-Ring: NOK (Japan)

- Back-up Ring: NOK (Japan)

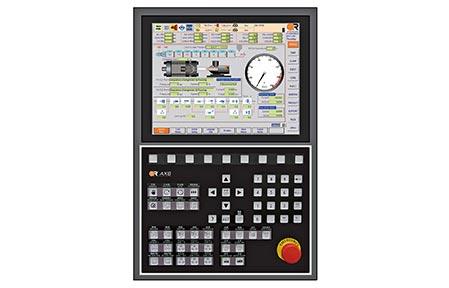

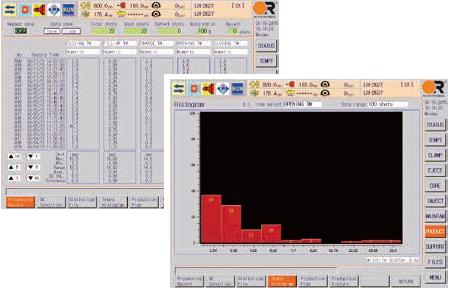

New Generation AX8 Control

Intuitive 15 inch touch screen framed with keyboard

The swivel mounted 15" LCD high resolution touch screen, graphical user interface, can be optimally positioned for each operator, allowing an easy setting position and easy access to the mould area.

Lighted on/off manual movement buttons for each axis.

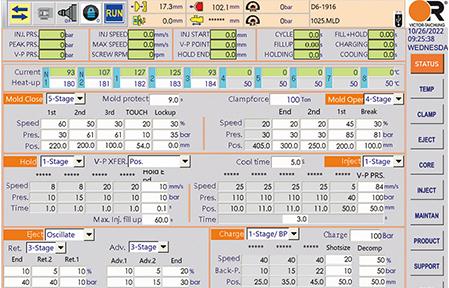

Simple Friendly Operation Interface

Mold settings can be transferred using a USB drive

The internal memory allows for up to 1000 set to be stored, the USB port enables molding condition files to be stored to an external USB memory stick.

Overall Setting Screen

- Single screen for setting clamp, ejector, injection, temperature, air-blast and charging etc.

- Great for quick setups and adjustments.

- Improves operator setup efficiency.

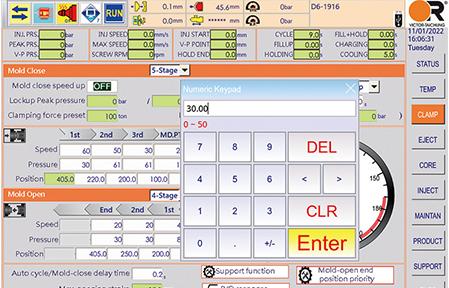

Pop-up Keyboards for Data and Text Entry

Touch screen panel/Pop-up keyboard for data and text entry. Drop down selection boxes for choosing items from a list.

SPC/SQC Production Management - Quality Control

Process cycle data maintains information over the last 10,000 cycles allowing for quick analysis of process history. This data can be printed, and save to USB sticker, for off line Excel analying.